There are circumstances when either quantity or complexity of a part requires secondary operations. Our secondary department performs necessary operations such as forming, winding, machining, roll-threading, tapping, testing and specialized packaging. The department uses various tools and equipment such as power presses, bench presses, foot presses, winders, deburr equipment, drill press, machining, testing and more.

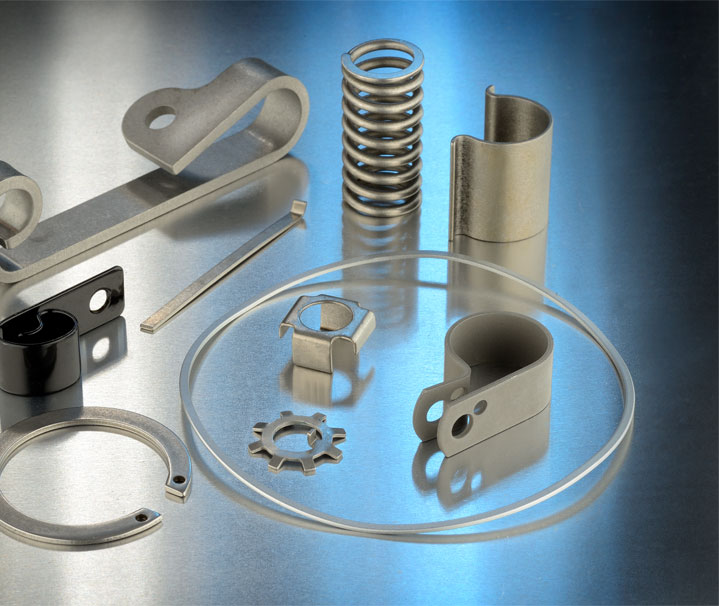

We can work in any alloy; carbon steel, stainless steel, brass, copper, aluminum, elgiloy, inconel, the list goes on to include wire of special shapes and even braided wire.

Generally focused on part numbers of lower volume or high complexity, the tooling cost in secondary is usually minimal. The variety of parts produced in secondary is staggering and they could move into power press, fourslide or our coiling area as demand increases.

A common first step in development of a new part is to create prototypes in our secondary area which prove out features and performance of the design. Many times, several iterations are used before committing the design to production tooling.

Our secondary area also performs special packaging and testing if those options are required by our customer. These special services can include individual bagging of parts, layer pack on tacky paper, other packaging options, special part marking, and/or 100% testing for force, torque, or dimensional features.

How can we help you?